Waste minimisation

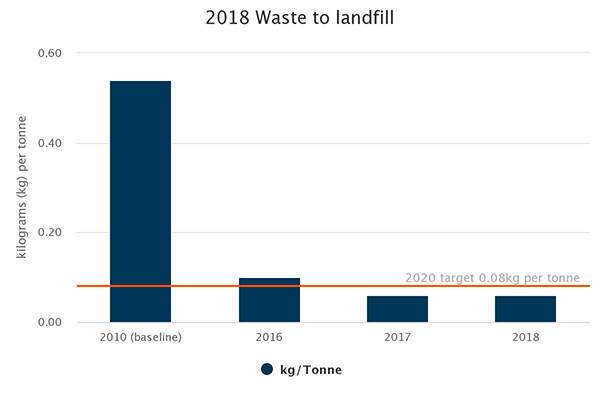

We remain ahead of our 2020 target of an 85 per cent reduction in waste to landfill per tonne of product based on the 2010 baseline figure, despite a two per cent year-on-year increase in 2018. This was largely due to an improvement project at Gosport concrete plant in Hampshire where we installed a new waste recycling facility including rain and groundwater collection, but had to remove around 200 tonnes of mixed material that could not be recycled. The new facility will virtually eliminate production waste.

The majority of our sites are included within a single contract with Biffa a national waste management company which enables us to control the process more effectively and maintain data on the quantity and types of waste being produced.

We are continuing our programme of investing in washing plants at our quarries to create a manufactured sand for use in concrete as a substitute for land-won and marine sand. A processing plant at Whatley quarry in Somerset produces manufactured sand which is being transported by rail to London and south-east England where supplies of land-won sand are becoming increasingly scarce.

-

Waste to landfill

2010 (baseline)

2016

2017

2018

Total tonnes

18,472

3,996

2,573

2,672 Kg/tonne product

0.54

0.10

0.06

0.06 When normalised for production changes at business line level, the 2018 performance is 0.07kg waste /tonne against a 2010 baseline of 0.50kg waste /tonne, showing a reduction of 85.8%.

Cement by-pass dust

All the bypass dust generated at our cement pants continues to be diverted from landfill. We are working on a research project to look at the potential to turn this material into an inert, non-hazardous product;

-

Cement specific waste – by-pass dust – tonnes

2010 (baseline)

2016

2017

2018

Produced

5,619

9,823

8,277

9,119 Landfilled

2,979

0

0

0 Diverted from landfill

47%

100%

100%

100%